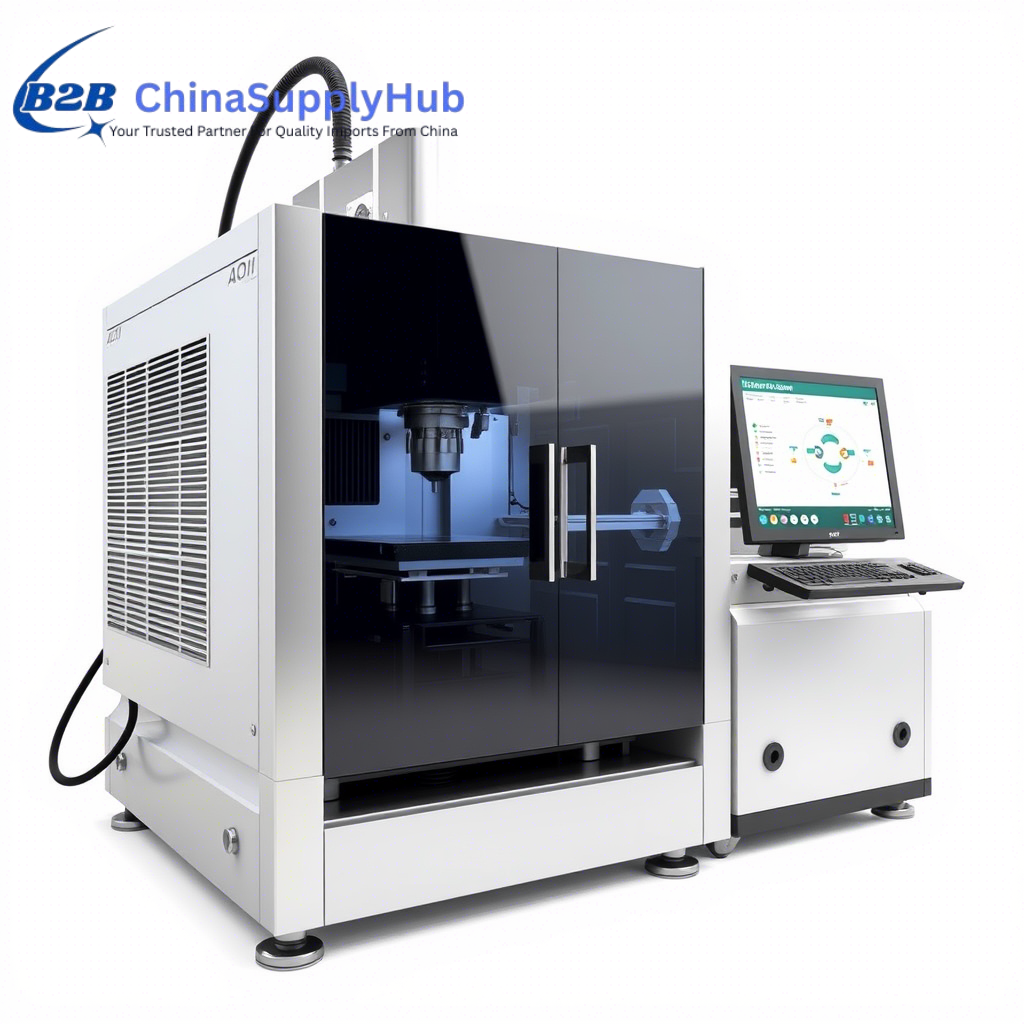

AOI (Automated Optical Inspection) | ChinaSupplyHub – High-Precision Quality Control Equipment for Electronics Manufacturing & Industrial Production

Description

At ChinaSupplyHub , we specialize in supplying premium-quality AOI (Automated Optical Inspection) systems used across electronics manufacturing, automotive electronics, consumer devices, and industrial automation sectors . These advanced inspection tools are sourced directly from verified Chinese manufacturers trusted by global OEMs in the automotive, electronics, medical device, and aerospace industries .

Engineered for high-speed defect detection, precision imaging, and seamless integration into production lines , our AOI systems meet international quality standards — making them suitable for use in:

- Surface Mount Technology (SMT) line inspection

- PCB assembly and component placement verification

- Post-reflow and post-solder paste printing checks

- Automotive sensor and ECU testing

- Smart factories and Industry 4.0 environments

As your trusted B2B partner between China and Russia , we ensure every AOI machine undergoes strict inspections for image resolution, software recognition accuracy, lighting uniformity, and compatibility with lead-free and RoHS-compliant processes before shipment. Our team collaborates exclusively with top-tier factories already integrated into major global supply chains — so you can be confident you’re receiving OEM-standard automated inspection solutions without risk or uncertainty.

In today’s complex geopolitical environment, securing reliable access to critical electronics manufacturing equipment like AOI machines has never been more important. At ChinaSupplyHub, we’ve built a sanction-compliant trade network that allows Russian businesses to import high-quality 2D and 3D AOI systems seamlessly — without payment restrictions, shipping delays, or communication barriers.

✅ Why Choose ChinaSupplyHub for AOI Machines?

- Verified Manufacturers

We only work with vetted suppliers who supply to leading global electronics and industrial brands — ensuring consistent quality and reducing procurement risks. - Quality Assurance

Every unit is thoroughly tested for defect detection speed, image clarity, false-positive rate, and compatibility with SMT and THT processes , meeting or exceeding IPC-A-610 and ISO 9001 standards. - Sanction-Free Trade Network

With access to VTB Bank accounts and direct factory partnerships in China, we offer seamless payment processing and logistics tailored for Russian B2B clients. - Full Support Services

From product sourcing and supplier quality management (SQM) to customs clearance and after-sales support, we provide full transparency and assistance at every stage of the procurement process. - Cost-Effective Solutions

By working directly with manufacturers, we eliminate intermediaries and pass on competitive pricing — helping you reduce costs while maintaining production yield and inspection accuracy.

⚙️ What Is an AOI Machine in Industrial & Electronics Manufacturing?

An AOI (Automated Optical Inspection) system is a vision-based quality control tool designed to automatically detect defects in manufactured products , especially in electronic assemblies, PCBs, and surface mount components .

Key Features:

- Available in various types including:

- 2D AOI Systems

- 3D AOI with height measurement

- Inline AOI for SMT lines

- Offline AOI for R&D and repair stations

- Designed for real-time defect detection, programmable inspection profiles, and AI-enhanced fault recognition

- Used in applications requiring zero-defect manufacturing, traceability, and compliance with IPC-A-610 and RoHS standards

Common Uses Across Industries:

- Pre- and post-reflow inspection in electronics production

- Component placement verification (missing, misaligned, tilted parts)

- Solder joint inspection (bridging, insufficient joints, polarity errors)

- Automotive electronics and safety-critical PCBs

- Medical device and industrial control module QA/QC

They are ideal for:

- Detecting solder paste imperfections and assembly faults

- Ensuring high-yield PCB production lines

- Integration into smart manufacturing and IoT-enabled systems

- Technical training centers and vocational education programs

- Export-focused EMS providers and contract manufacturers

💼 Who Can Benefit From Our AOI Systems?

Whether you’re:

- Managing an electronics manufacturing services (EMS) provider

- Operating an automotive or aerospace PCB assembly line

- Running a technical school or vocational training center

- Supporting R&D or prototype development labs

- Distributing industrial electronics equipment across Russia and CIS countries

ChinaSupplyHub offers:

💰 Competitive Pricing

🚚 Fast, Reliable Delivery via Multiple Logistics Channels

📞 Dedicated Multilingual Support in Russian, English, and Chinese

📋 End-to-End Service — from Product Selection to Customs Clearance

Reviews

There are no reviews yet.