Injection Molding Machine | ChinaSupplyHub – High-Performance Plastic & Rubber Molding Equipment for Industrial Production

Description

At ChinaSupplyHub , we specialize in supplying premium-quality injection molding machines used across a wide range of plastic manufacturing, automotive parts production, consumer goods, and industrial component fabrication sectors . These essential production tools are sourced directly from verified Chinese manufacturers trusted by global OEMs in the automotive, electronics, medical, and packaging industries .

Engineered for high precision, energy efficiency, and long-term reliability , our injection molding machines meet international quality standards — making them suitable for use in:

- Mass production of plastic components

- Automotive interior and exterior part manufacturing

- Medical device and packaging production

- Consumer electronics housing and connectors

- Custom mold development and small-batch prototyping

As your trusted B2B partner between China and Russia , we ensure every machine undergoes strict inspections for clamping force accuracy, injection speed control, mold alignment, and control system performance before shipment. Our team collaborates exclusively with top-tier factories already supplying to major global industrial equipment brands — so you can be confident you’re receiving OEM-standard molding solutions without risk or uncertainty.

In today’s complex geopolitical climate, securing reliable access to critical production equipment like injection molding machines is more important than ever. At ChinaSupplyHub, we’ve built a sanction-compliant, fully structured trade network that allows Russian businesses to import high-quality hydraulic, all-electric, and hybrid injection molding systems seamlessly — without delays, payment restrictions, or communication barriers.

✅ Why Choose ChinaSupplyHub for Injection Molding Machines?

- Verified Manufacturers

We only work with vetted suppliers who supply to leading global machinery and industrial brands — ensuring consistent quality and reducing procurement risks. - Quality Assurance

Every injection molding machine is thoroughly tested for injection pressure, clamping tonnage, cycle time stability, and energy consumption , meeting or exceeding ISO 10791 and GOST standards. - Sanction-Free Trade Network

With access to VTB Bank accounts and direct factory partnerships in China, we offer seamless payment processing and logistics tailored for Russian B2B clients. - Full Support Services

From product sourcing and supplier quality management (SQM) to customs clearance and after-sales support, we provide full transparency and assistance at every stage of the procurement process. - Cost-Effective Solutions

By working directly with manufacturers, we eliminate intermediaries and pass on competitive pricing — helping you reduce costs while maintaining productivity and part quality.

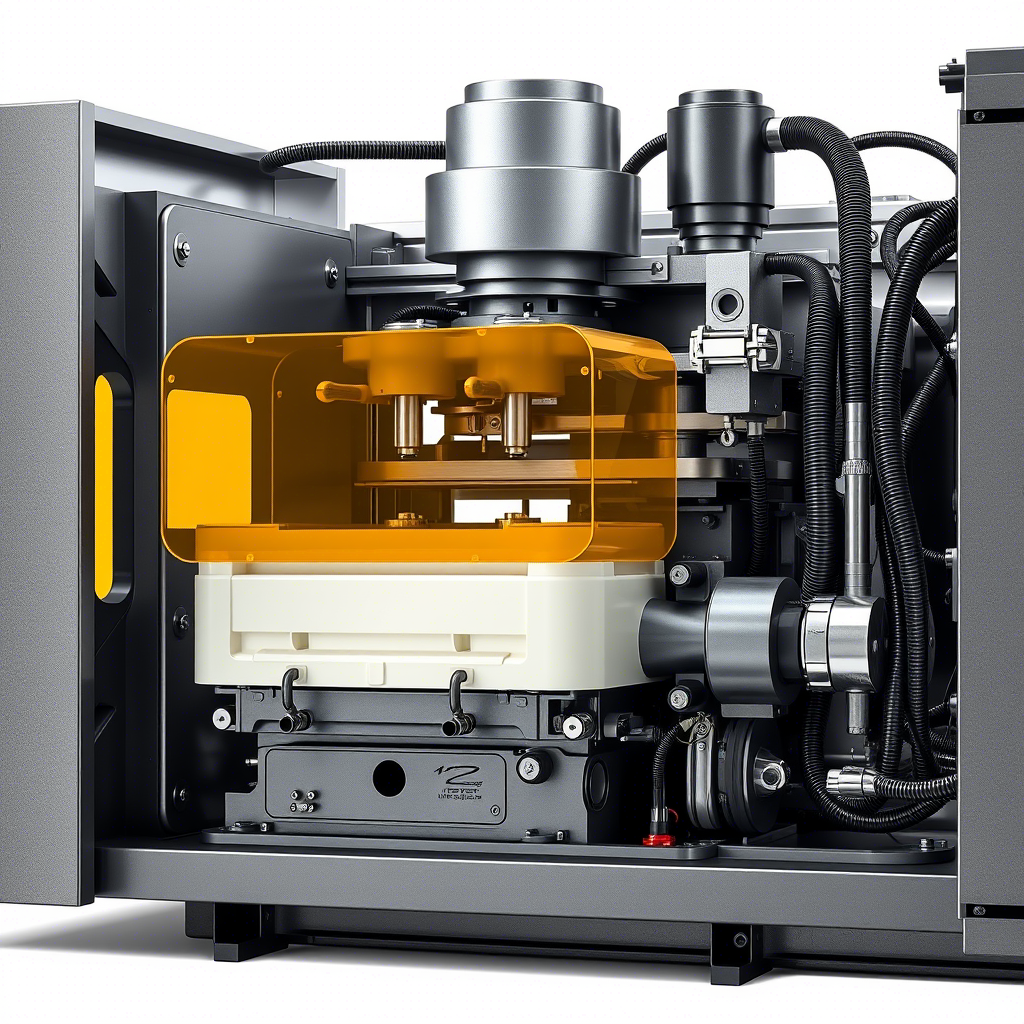

⚙️ What Is an Injection Molding Machine?

An injection molding machine is a highly automated industrial system designed to mass-produce complex plastic or rubber parts by injecting molten material into a precisely machined mold cavity under high pressure.

Key Features:

- Available in various types including:

- Hydraulic Injection Molding Machines

- All-Electric (Servo) Models

- Hybrid Servo-Hydraulic Systems

- Vertical and Horizontal Configurations

- Designed for high repeatability, tight tolerances, and compatibility with automation lines

- Used in applications requiring precision molding, fast cycle times, and multi-cavity production

Common Uses Across Industries:

- Automotive (dashboards, bumpers, lighting units)

- Electronics (housings, connectors, switches)

- Medical (syringes, diagnostic devices, surgical tools)

- Packaging (caps, containers, bottles)

- Household appliances and toys

They are ideal for:

- Mass production of plastic and rubber parts

- Rapid prototyping and tooling trials

- Integration into smart factories and Industry 4.0 setups

- Custom mold development and trial runs

- Technical training and vocational education centers

💼 Who Can Benefit From Our Injection Molding Machines?

Whether you’re:

- Running an industrial workshop or plastic manufacturing facility

- Managing a mold design or prototyping center

- Operating a technical school or vocational training center

- Distributing industrial machinery across Russia and CIS countries

- Supporting automotive, medical, or consumer goods production teams

ChinaSupplyHub offers:

💰 Competitive Pricing

🚚 Fast, Reliable Delivery via Multiple Logistics Channels

📞 Dedicated Multilingual Support in Russian, English, and Chinese

📋 End-to-End Service — from Product Selection to Customs Clearance

Reviews

There are no reviews yet.